Your cart is currently empty!

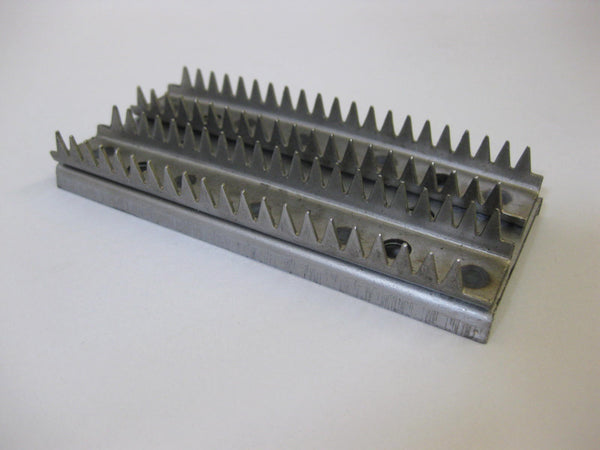

Buffing Rake Kit

1900-K$ 23.94

Buffing Rake Kit

$ 23.94

The Buffing Rake is used to clean the spent or old hard compound out of buffing wheels. It also trues and levels the buffing wheels keeping them balanced. A dished buffing face can be raked flat or level. If the buffing face becomes dished, it's easier for the buff to grab the part.

The buffing process produces heat due to friction between the buff and the part. The hot buff keeps the compound in a soft state, which is close to melting. Once the buff is no longer in contact with the part, there is no friction, the buff cools off and the compound hardens. When this happens, the buff needs to be raked to remove the spent compound and create a nice fresh nap to accept new compound. If the buff is used in combination with a cutting compound and is constantly being used, the buff does not need to be raked until you stop buffing for more than 3 minutes. But, the finishing / coloring buff needs to be raked every 5 minutes because that process does not build up as much heat. Without the heat the fibers have a tendency to stick together. The raking process produces a fine nap which will produce a clearer finish.

Directions for use: While the buffing wheel is spinning move the rake into the buff slow enough so that the rake is not pulled from your hand. Apply very light pressure until you see a fine nap on the buff.

Safety first – Always wear adequate & proper EYE, EAR, FACE, BODY and RESPIRATORY PROTECTION while polishing and buffing.

Made in the USA